MGICLab-LN55K Pro

MGICLab-LN55K Pro* Automated Liquid Nitrogen Storage System, equipped with aerospace-grade high-vacuum double-layer thermal insulation tank, can effectively ensure the sample temperature balance, and guarantee the sample stability and safety. It also has automatic liquid nitrogen replenishment, monitoring alarm, emergency safety protection and other deep low-temperature cold chain security measures, which can ensure the sample safety for more than 288 hours even in case of liquid nitrogen outage or other force majeure factors. The full-process automated access makes the sample storage easy and convenient.

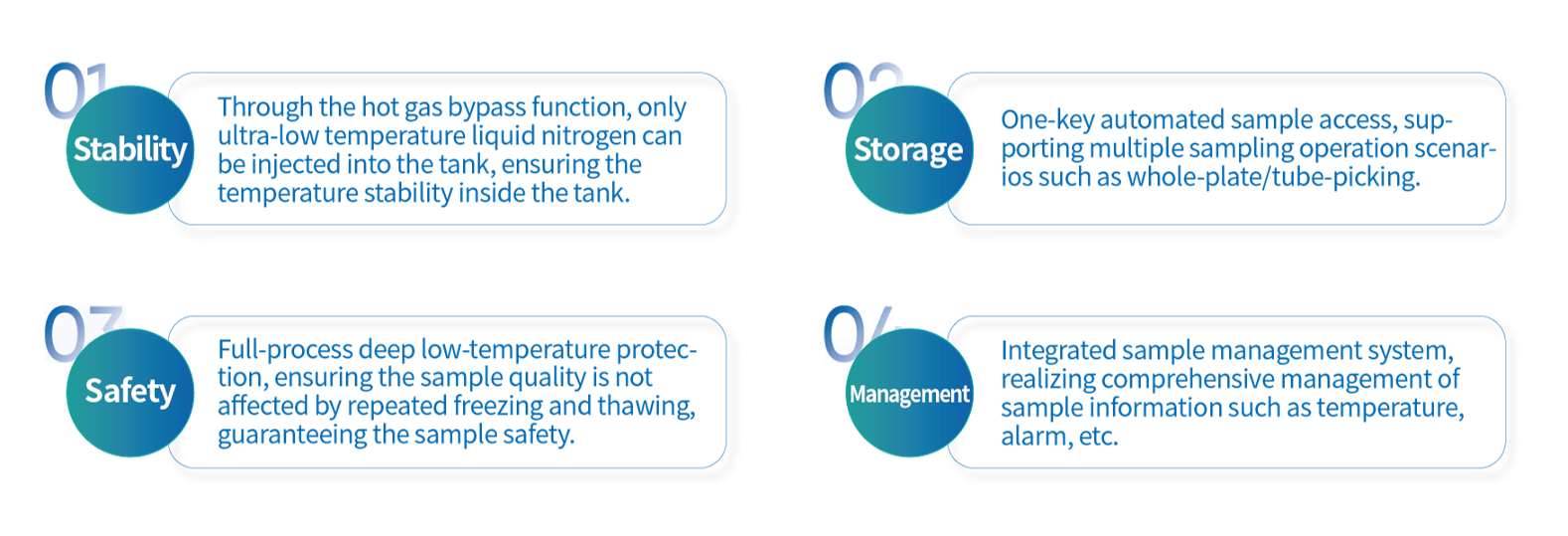

Features

Single/whole box automated access: Supports reservation, batch operation, fragment sorting, flexible access and other multiple access scenarios.

|

Full-process temperature≤ -150°C for access: Automatic pre-cooling in the tube-picking area, liquid nitrogen transfer, ensuring sample quality. |

Smart IoT, real-time sample traceability: Intelligent error prevention, real-time anomaly alert, comprehensive operation log, ensuring sample data real-time tracking. |

|

Performance Parameter

|

MGICLab-LN55K Pro |

|

|---|---|

|

Storage Consumables |

Compatible with SBS standard format 0.5ml, 0.75ml, 1ml, 2ml, 5ml cryogenic tubes in cryogenic box. |

| Storage Capacity |

0.5 mL ≥ 55K tubes; 2 mL ≥ 24K tubes. |

| Storage Temperature | The top of the tank is < -180°C, and the tube-picking area is ≤ -150°C. |

|

Liquid Nitrogen Consumption |

One-time injection usage time≥12Days; Static liquid nitrogen consumption 15L/Day. |

| In-out Warehouse Unit | Can perform whole-box or single-tube sample in-out warehouse tasks. |

| Remote Alarm System | Has remote communication function, sends real-time device status via WeChat, SMS. |

| Fragment Sorting | The system can sort the scattered sample tubes according to the sample information and a certain logic. |

| Sample Protection | Has timeout return function, time can be set. |

| Monitoring System | The system is equipped with monitoring cameras, can see the internal environment in 360°. |

Main Performance and Technical Indicators

System Parameter

- Equipment installation

Voltage/Frequency: 220V/50Hz

Installation Conditions: Minimum door width ≥ 1.4 meters

Device Height: Device height ≥ 2.6m

Liquid Nitrogen Replenishment: Equipped with standard interface for liquid nitrogen tower pipeline docking

Floor Load Capacity:≥700 kg/㎡

Sequencer Products: SEQ ALL

Sequencer Products: SEQ ALL

Technologies

Technologies Applications

Applications Online Resources

Online Resources Data Bulletins

Data Bulletins Service & Support

Service & Support Global Programs

Global Programs Introduction

Introduction Newsroom

Newsroom Doing Business With Us

Doing Business With Us Creative Club

Creative Club